What are PCBs?

What are PCBs?

Polychlorinated biphenyls (PCBs) are mixtures of synthetic organic chemicals; there are no natural sources of PCBs. PCBs were used in hundreds of industrial and commercial applications in the United States, including:

- Electrical, heat transfer, and hydraulic equipment

- Plasticizers in paints, plastics, and rubber products

- Pigments and dyes

The manufacturing of PCBs ceased in 1977 due to concern over their harmful health effects (toxicity) and persistence in the environment. PCBs have been demonstrated to cause a variety of adverse health effects.

Understanding the terms used within the federal regulations is vital to understanding how these regulations apply to items that may or are known to contain PCBs in concentrations of 50 ppm or more. Some of the definitions contained in the regulations are provided below:

Capacitor: A device for accumulating and holding a charge of electricity and consisting of conducting surfaces separated by a dielectric. Three types of capacitors are as follows:

- Small Capacitor, which contains less than 3 pounds of dielectric fluid,

- Large High-Voltage Capacitor which contains 3 pounds or more of dielectric fluid and operates at 2,000 volts or more, and

- Large Low-Voltage Capacitor which contains 3 pounds or more of dielectric fluid and operates below 2,000 volts. The following assumptions may be made if the actual weight of the dielectric is unknown. A capacitor with total volume of less than 100 cubic inches may be considered to contain less than 3 pounds of dielectric fluid. A capacitor with total volume of more than 200 cubic inches may be considered to contain more than 3 pounds of dielectric fluid. A capacitor with total volume between 100 and 200 cubic inches may be considered to contain less than 3 pounds of dielectric fluid if the total weight of the capacitor is less than 9 pounds.

Fluorescent Light Ballast: A device that electrically controls fluorescent light fixtures and that includes a capacitor containing 0.1 kilograms or less of dielectric.

High Concentration PCBs: PCBs that contain 500 ppm or greater PCBs, or those materials that USEPA requires to be assumed to contain 500 ppm or greater PCBs in the absence of testing (e.g., capacitors or transformers with nameplates that indicated the presence of Askarel, Pyranol, Inerteen, or other high-concentration PCB dielectric fluids).

Low-Concentration PCBs: PCBs that are tested and found to contain less than 500 ppm PCBs, or those PCB-containing materials that USEPA requires to be assumed to be at PCB concentration of less than 50 ppm (e.g., untested mineral oil dielectric fluid).

PCB Article: Any manufactured article other than a PCB container (see definition to follow) that contains or must be assumed to contain PCBs at concentration of 50 ppm or more and whose surfaces have been in contact with such PCBs.

PCB Container: Any package, can, bottle, bag, barrel, drum, tank, or other device that contains PCBs or PCB Articles and whose surface(s) has been in direct contact with PCBs.

PCB-Contaminated: a non-liquid material containing PCBs at concentrations of 50 ppm or greater but less than 500 ppm; a liquid material containing PCBs at concentrations of 50 ppm or greater but less than 500 ppm or where insufficient liquid material is present for analysis; a non-porous surface concentration of more than 10 micrograms per 100 square centimeters but less than 100 micrograms per 100 square centimeters as measured by a standard wipe test defined at 40 CFR 761.123.

PCB-Contaminated Electrical Equipment: Any electrical equipment that contains 50 ppm or greater PCBs but less than 500 ppm PCBs. Oil-filled electrical equipment other than transformers that contain less than 3 pounds of dielectric fluid, circuit breakers, reclosers, oil-filled cable, and rectifiers whose PCB concentration is unknown must be assumed to be PCB-contaminated electrical equipment. Transformers that contain less than 3 pounds of dielectric fluid, circuit breakers, reclosers, oil-filled cable, and rectifiers may be assumed to contain less than 50 ppm PCBs (and therefore not subject to the TSCA regulations) unless the equipment nameplate indicates that the equipment was designed to contain Askarel, Pyranol, Inerteen, or other high-concentration PCB dielectric fluids. However, electrical equipment manufactured after July 2, 1979 may be assumed to be non-PCB (i.e., contains less than 50 ppm PCB).

PCB Equipment: Any manufactured item, other than a PCB Container or PCB Article that contains a PCB Article or other PCB Equipment. Examples of PCB equipment include microwave ovens, electronic equipment, and fluorescent light ballasts and fixtures.

PCB Item: Any PCB Article, PCB Article Container, PCB Container, or PCB Equipment, or anything that deliberately or unintentionally contains or has a part of it any PCB or PCBs.

PCB Transformer: Any transformer that contains 500 ppm or more PCBs.

PCB Waste: Those PCBs and PCB items that are subject to the disposal requirements of 40 CFR 761 Subpart D.

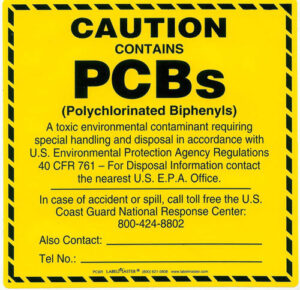

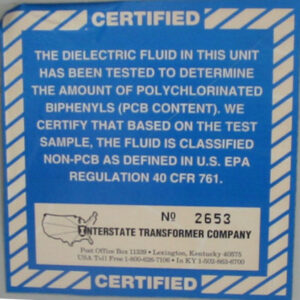

PCBs are still present in industrial settings, particularly in old equipment. Although not widely found, some tenant equipment may still contain PCBs. PCBs may be found in electrical equipment made before 1977 including capacitors, transformers, circuit breakers, reclosers, voltage regulators, switches, oil-filled electrical transmission cables, and fluorescent light ballasts. Newer electrical equipment containing dielectric fluid does not contain PCBs and is clearly labeled “No PCBs.”

PCBs are still present in industrial settings, particularly in old equipment. Although not widely found, some tenant equipment may still contain PCBs. PCBs may be found in electrical equipment made before 1977 including capacitors, transformers, circuit breakers, reclosers, voltage regulators, switches, oil-filled electrical transmission cables, and fluorescent light ballasts. Newer electrical equipment containing dielectric fluid does not contain PCBs and is clearly labeled “No PCBs.”

At BWI Marshall and Martin State Airports, PCB-containing items are thought to be limited to older ballasts (small transformers) used in fluorescent light fixtures. Ballasts must be handled as a toxic waste unless marked “No PCBs”. Each year, airport electricians replace a number of light ballasts; thus, the number of PCB-containing items will decrease over time.

Toxic substances in Maryland are regulated by both USEPA and the MDE. The U.S. EPA regulates toxic substances, including PCBs, under the Toxic Substances Control Act (TSCA). The TSCA program is implemented at the federal level; however, the TSCA regulations allow states to regulate specific toxic substances, such as PCBs, under their own hazardous waste laws.

Toxic substances in Maryland are regulated by both USEPA and the MDE. The U.S. EPA regulates toxic substances, including PCBs, under the Toxic Substances Control Act (TSCA). The TSCA program is implemented at the federal level; however, the TSCA regulations allow states to regulate specific toxic substances, such as PCBs, under their own hazardous waste laws.

In Maryland, PCB-containing light ballasts are regulated as a universal waste [i.e., lamps, including fluorescent lamps; batteries; pesticides that are part of a recall or collection program; mercury-containing thermostats; and fluorescent light ballasts that contain PCBs] under Maryland’s hazardous waste regulations. Under MDE regulations, fluorescent light ballasts containing PCBs are not subject to the full range of hazardous waste regulations.

The regulations governing PCBs apply only to items and materials that contain greater than 50 parts per million (ppm) of PCBs or materials generated during a cleanup of spilled PCBs that originally had concentrations of 50 ppm or more. More stringent requirements are set for materials that contain PCBs in concentrations of 500 ppm or more. Equipment that typically contains PCBs but has an unknown PCB concentration must be managed as if it contained PCBs in concentrations of 50 ppm or greater but less than 500 ppm. Suspected PCB-containing light ballasts at BWI Marshall would fall into this latter category since their PCB content is unknown.

See the PCB Related Definitions section above for additional clarification on the terms used in the regulations and understanding how these regulations apply to materials at your site.

Federal and state regulations require that PCB wastes be stored and disposed of in specific ways. Records must be kept to show that these requirements have been met. Specific regulatory requirements govern the timely and accurate reporting to environmental agencies.

Tenants should have standard operating procedures in place for handling PCB waste. For instance, PCB-containing light ballasts should be removed from service and temporarily stored in a leakproof container in a designated location, such as a covered shed, with secondary containment. A licensed contractor should periodically remove the used ballasts for disposal.

Managers and supervisors whose organizations maintain fluorescent lights should make sure that their employees know the proper procedures for handling and storing light ballasts. Additionally, employees should not open light fixtures and should report any leaking substances to maintenance personnel.

One of the requirements of tenant leases is that tenants must adhere to the requirements of the applicable tenant directives and associated regulations. Not adhering to these requirements can impact the standing of the tenant lease.

Additionally, a federal penalty exists for any person who “knowingly or willfully” violates any provision of U.S. Code Section 15, under which TSCA is codified. A violation of Section 15 is a misdemeanor that is punishable by up to one year in prison and up to $25,000 for each day of violation. TSCA also contains “private attorney general” provisions that allow any person to commence a civil action against any other person or entity that is alleged to be in violation of TSCA.

You can find additional information on this topic through the following links: